|

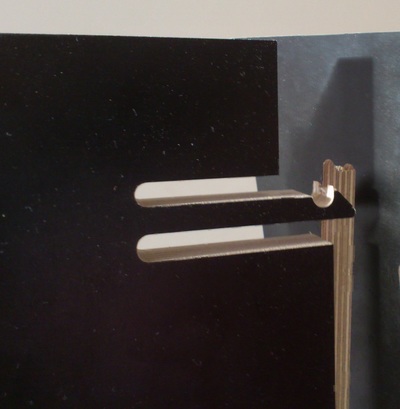

With the right dimensions, it is possible to design a plywood piece which can only be put into position by bending it. This can be useful in many ways for objects assembled with plywood pieces. An example is this part of my couch: There is no way to just insert this piece by keeping it flat. There are holes in the thick vertical frame components to insert the ends of this thin piece; you need to insert one narrow side in at one end and bend the plywood in order to squeeze the other side into the compartment at the other end. If you’re wondering what the function of this piece is: it’s to prevent the rear horizontal slats (where you back would be if you sat on the couch) from moving forwards: It uses a dovetail catch to grab onto back of the top slat. I will delve more into dovetail catches in a future post. A variant of this is this piece, which was the way I prevented the top of this cabinet from sliding forwards: The bendable piece is slid into two holes in alignment. One is in the underside of the top piece of the cabinet, and one in an adjacent piece directly under. Since that adjacent piece can’t move, sliding something through that and into the underside of the top piece means that the top piece is prevented from moving. All you need is enough squeezable distance to prevent this piece from falling out. Another example is this a snap-lock. Similar to a common plastic snap-lock used for things like bags and rucksack straps, this involves a piece of plywood shaped with a hook and whose ‘arm’ is cut thin enough to be able to bend as the unit is inserted into a slot. The hook end needs to be sloped so that the arm is gently allowed to bend as you move it further into the slot. Once it gets far enough, the arm will snap back into its preferred position and the lock will secure it. The arm in the example above is about 6 mm thick, but probably the best thickness is slightly thinner.

Comments

|

AuthorI'm Nicolaas, a software engineer with a creative streak. ArchivesCategories

All

|

RSS Feed

RSS Feed