|

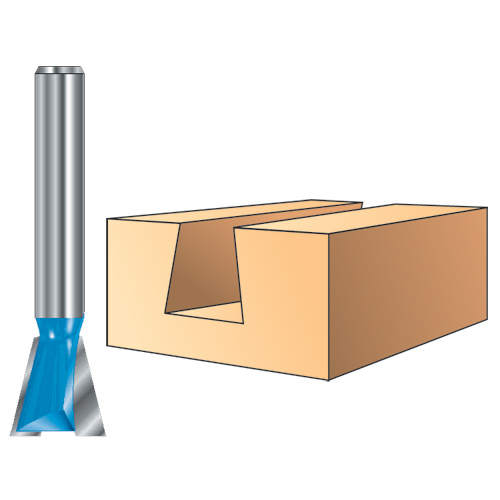

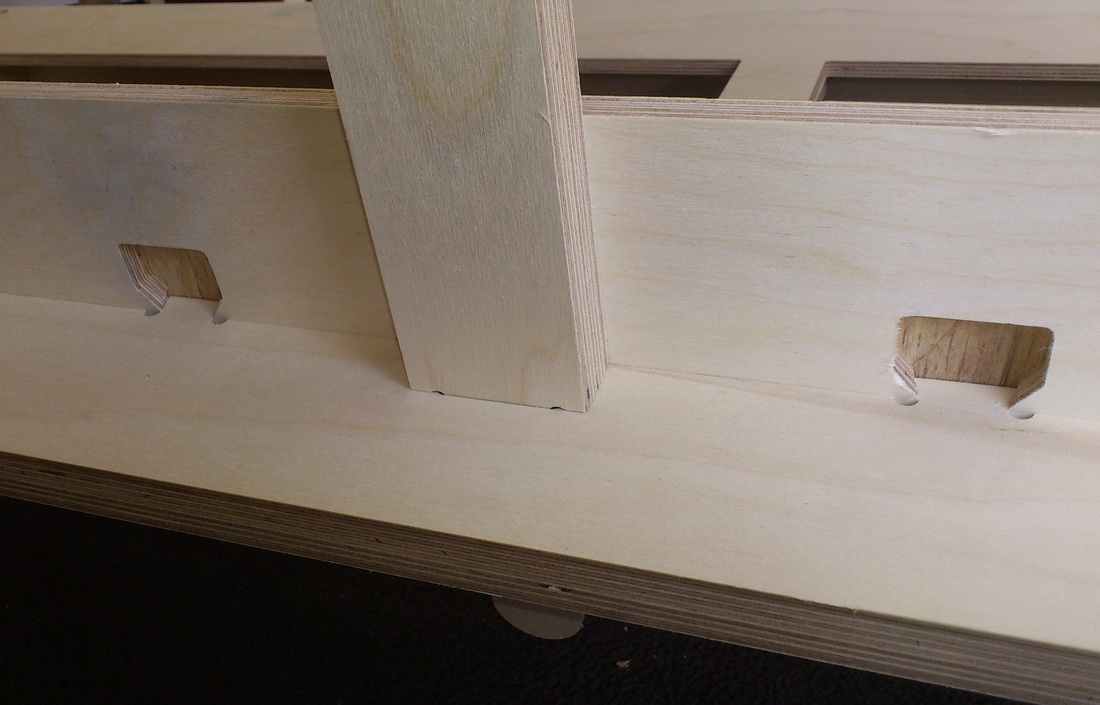

This is a way I have used to enable one piece to ‘grab’ another without the use of a slot joint, or even a screw, nail, bolt or glue. Using a dovetail bit, a CNC router can mill a groove into plywood in which the gap at the surface is narrower than at the bottom of the groove. If you can slide a dovetail-shaped tab into this groove, then the piece attached to the tab will grab onto the piece with the groove with a lot of strength. I have used this idea in most of my furniture pieces so far to avoid using glue/screws/etc. The only weakness of course is the chance that the tab could slide out again the way it came in. All you need to do therefore is to prevent movement in this one direction - and I will talk about that in the next post. Here is a view of a dovetail tab and a groove milled using a dovetail bit in the CNC router: The extra space in front of where the dovetail tab comes to rest is needed to enable the tab to descend to its final depth first, before sliding into the groove itself. Below is the final position of the dovetail-shaped tab. As you can see, if you try to pull it upwards, it won't move. Here is a good view of dovetail catches used in my couch:

Comments

|

AuthorI'm Nicolaas, a software engineer with a creative streak. ArchivesCategories

All

|

RSS Feed

RSS Feed